Automation

When it comes to growth, your decision should be automatic.

Capabilities

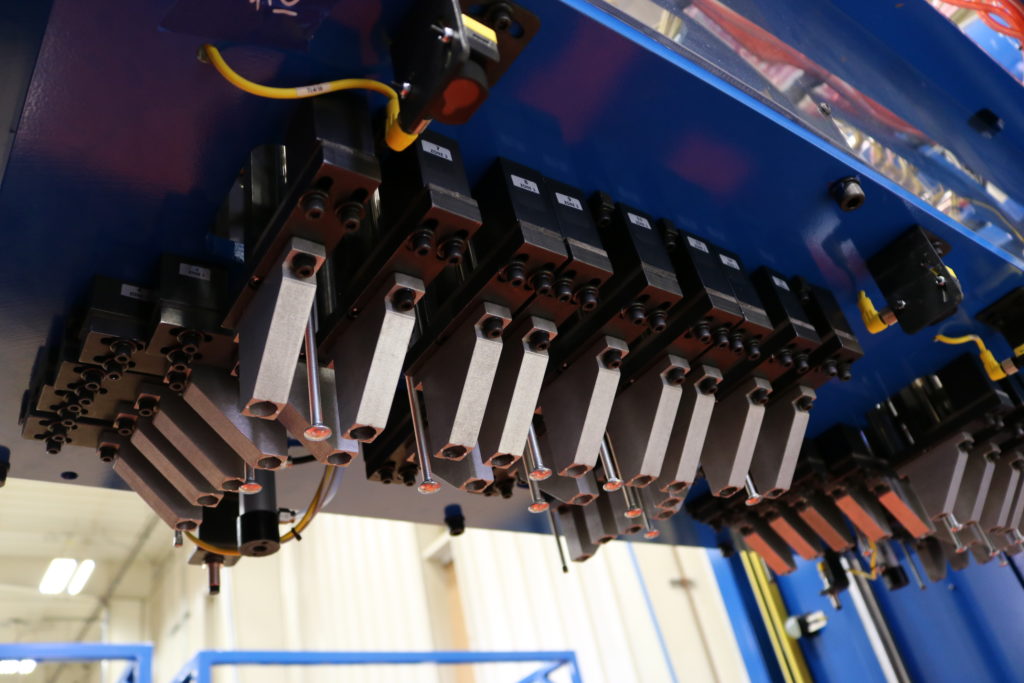

HS maximizes productivity and optimizes part processing by integrating the right technologies into a solution to meet your production needs. We can interface with existing equipment, to compliment your current process, or develop an independent solution for you to streamline production. Different levels of part processing require different assembly solutions which we create depending on your technical specifications. Contact us to achieve the right automation assembly solution for you.

Markets served: Aerospace, Automotive, Consumer and Military

We seek to reduce cost and enhance production for our customers by offering versatile modular mainframes and stand-alone stations. The modular mainframes are designed to have the nesting swapped out to process different parts to meet current or future production needs. As parts become obsolete, new nesting is made for the existing modular mainframes to help reduce cost. We work with you towards the best solution for your situation. Give us a call to experience the difference that makes firsthand.

Markets served: Aerospace, Automotive, Consumer, Military

Material handling concentrates on reducing time, cost of production but also needs to fit within your equipment to make sure your current process grows more efficient and effective. Those are the things we do best, give us a call and we’ll show you.

Markets served: Aerospace, Automotive, Consumer, Food, Military and Shipping & Freight

Most HS customers have a diverse set of automation needs. We work with you to meet those requirements so you can stay focused on production and keeping your customers happy. Many of our automation customers also work with our Tool & Die team. HS built our reputation on molding, particularly on injecting molding. When it comes to processing plastic, our team works seamlessly to provide customers with the tools they need.

Markets served: Aerospace, Automotive, Consumer, Food, Military and Shipping & Freight

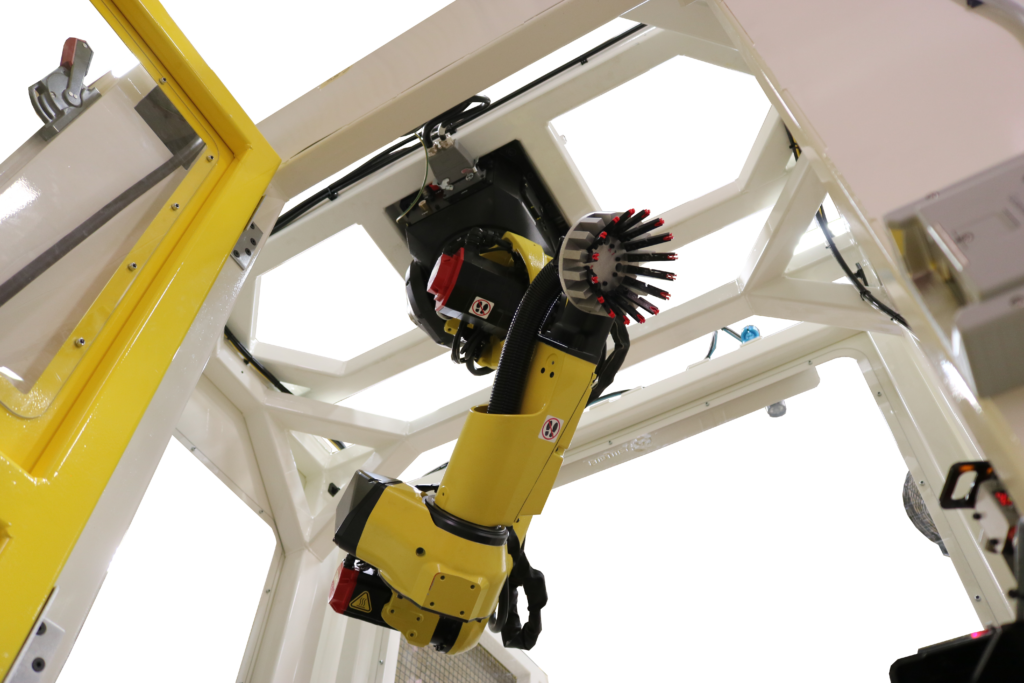

Customers benefit with robot integration through improved quality, efficiency, and reduced cost. Assigning specific manufacturing tasks to robots keep employees safer, maintain a rapid workflow and reduces material waste through repeatability. When considering robot integration, HS places value on educating our customers on the fiscal tradeoffs of robot maintenance and repair to make sure you can always make the decision that best suits your company.

Markets served: Aerospace, Automotive, Consumer and Food

From vision guided robotics to thermal, IR and 3D imaging; we feed on optical challenges. We apply optical and mechanical design, image processing techniques, and robust PLC programming to the tools we create for our customers. Our vision integration services aim to increase efficiency, repeatability, and precision. Discover the full range of our capabilities by giving us a call.

Markets served: Aerospace, Automotive, Consumer, Food and Shipping & Freight

- Adhesive Dispensing

- Bowl Feeding

- Clip Driving

- Cobot Collaborative Robots

- Fastening, Fixtured Conveyors

- Flex Feeding

- Force and Distance

- Gauging

- Joining

- Leak Testing

- Palletized Conveyor

- Part Marking

- Press Tending

- Pressing

- Robotic Assembly

- Riveting

- Rotary Index Dial Table

- Sonic Welding

- Screwdriving

- Vision Inspection

- Vision Verification

- Walking Beam

- Welding

Process

HS has a team of application engineers to work directly with your team. We strive to understand the full scope of your manufacturing process and needs, but also develop a robust concept to fit them. From simple to complex automation, our application engineers work with seasoned mechanical and controls engineers, builders, and electricians to provide you with a comprehensive solution tailored for your application.

We have a dedicated team of project managers who will guide your projects from kick-off all the way through post-installation support. One will become a single point of contact to guide you through design reviews, keeping project scope on track, maintaining the timeline, and maintaining an open issue list. Our project management team is key to ensure customer satisfaction.

HS is known for building solid robust equipment to meet your manufacturing needs. Our team, design team, utilizing 3D solid model designs, will combine our expertise in equipment design with your product knowledge to create the unique solution to meet your manufacturing needs. We work closely with your team to obtain concept approval and then we detail and deliver a comprehensive design along with complete documentation delivered to our customers.

Our solutions range from individual manual stations to complex robotic solutions. Our team of Controls Engineers and technicians have the knowledge and background to provide you with the comprehensive design to meet your manufacturing needs. We work closely with your team to obtain concept approval and then detail and deliver a comprehensive design along with complete documentation delivered to our customers.

Our experienced build team will bring your equipment design to reality on our shop floor. Build begins with integrating purchased components with custom components we fabricate. Once equipment is constructed, programming begins. We extensively test the equipment to prepare for acceptance by your team prior to shipment. We strive to ensure your complete satisfaction before your equipment ever arrives to your facility.

We have successfully installed equipment across North America and on two continents. We have the support required for shipment, equipment setup, and to keep your production running effectively.

We’re a one-stop shop for our customers–with expertise in consulting, ROI analysis, project management, design, fabrication, assembly and more. This work is about anticipating our customers’ needs and surpassing their expectations.

Doug Oler

Director of Automation Sales, HS Inc.

We’re an automation integrator: translating the various steps of production into a single automation line or cell that works flawlessly. From initial concept to launch, we partner with customers to build the machines they need—taking part volume, operator needs, quality control and budget constraints into consideration.

Request Quote